Looking for a pair of selvedge jeans, a denim jacket, a loopwheeled T-shirt, or anything that is made slowly and purposefully? We earn a small commission when you buy here:

Denimhunters is a knowledge portal about denim. Since 2011, we’ve helped denim lovers make educated buying decisions in the pursuit of timeless and adaptable wardrobes stocked with well-made essentials.

With our Raw Denim guides, The Rebel Essentials, and our Well-Made Essentials, we will help you find the best of raw selvedge jeans, leather boots, denim jackets, heavy flannels, and much more. Start your hunt with the guides below.

RAW SELVEDGE JEANS

Looking for the bar-none best pair of selvedge jeans? You’ve got options. We’ve cut it down to a dozen makers of the best men’s selvedge jeans.

DENIM SHIRTS

A well-faded raw denim shirt is a grail for most denimheads. But it’s tougher to fade than your jeans. Here’re 20 shirts worth the work.

DENIM JACKETS

If you need a jacket that can stand the cold and look great for decades, this buying guide is the perfect place to start your hunt.

The Denim Encyclopedia by Denimhunters is a knowledge base with answers to frequently asked questions about denim and jeans, as well as explanations of how denim and jeans are made.

The Encyclopedia is divided into sections, each with its own homepage where its entries are listed with brief descriptions and links to read more. The Encyclopedia is continuously updated with new entries.

DENIM EXPLAINED

This section of the Encyclopedia is home to everything that relates specifically to the denim fabric. You’ll find answers to all your questions about denim and how it’s made.

JEANS ANATOMY

Many of the features that define blue jeans started as pragmatic solutions to the problems. Here you’ll find answers to questions about the details of jeans and how they’re made.

VOCABULARY

Every business has its own vocabulary. This section lists and explains the most common and frequently used terms from the world and jeans and denim.

A-Z

Here you’ll find all entries of the Denim Encyclopedia in alphabetical order. Each entry is explained briefly – you can read more by clicking the link.

Cuffing is not only a practical way of making your jeans shorter without having to cut and sew, it also looks great.

This guide explains the eight most common ways to cuff your jeans.

If you need to wash your jeans, but you don’t want to change the way they look, wash them by hand.

It’s the most gentle way you can wash your jeans because there is less agitation, which less risk of unwanted creases.

In this section of the Denim Encyclopedia, we investigate and debunk the myths about how to wash raw denim, including not washing for 6 months, ocean washing, dry cleaning and more.

An Island in The Bay: Tellason Brand Profile

Founded in 2008, Tellason has always stuck to its principles: No-nonsense design, Made in USA, and that approachable Californian attitude.

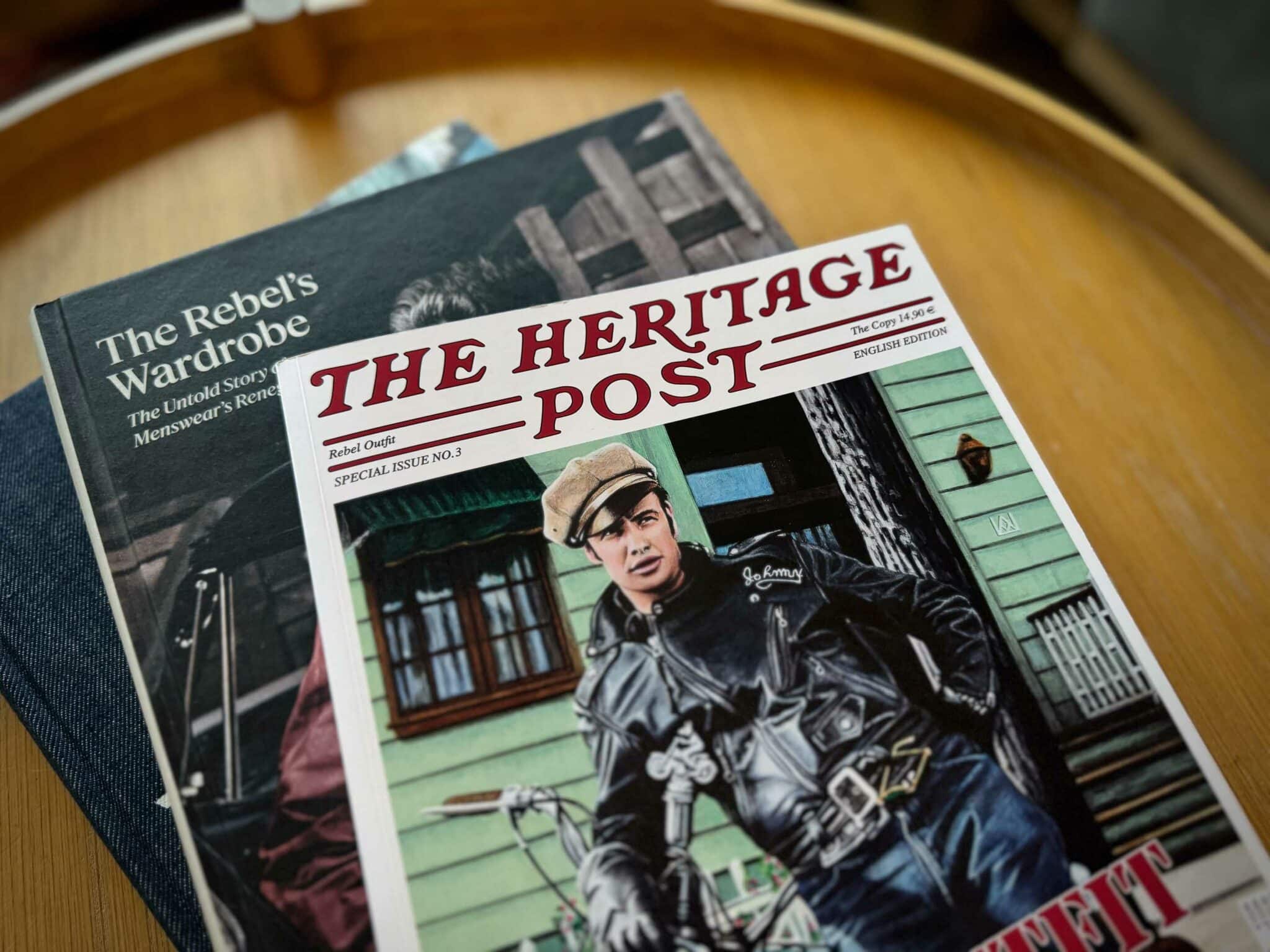

It’s in the Post: ‘Rebel Outfit’ in a Special Issue of The Heritage Post

Bryan and Thomas have written and edited a special issue of The Heritage Post themed ‘Rebel Outfit’, available in both English and German.

This Only Happens in Movies: Review of ‘Denim Hunter’ Film

Not to be confused with our website, Denim Hunter is a film about Swedish denim collector Viktor Fredbäck and his quest to complete his vintage denim collection.

2023 Gift Guide: Presents for the Denim Lover in Your Life

If you’ve got a denim lover on your list this year, you’ll find something perfect here. Twenty well-made and essential pieces from some of our favourite makers.

A Little Bit Extra: Big John XXXX-Extra Review

Big John have done it again! The Big John XXXX-Extra jeans prove that the Japanese pioneers do middleweight selvedge denim better than most.

10 Fast-Fading Lightweight and Middleweight Selvedge Jeans

10 of pairs lightweight and middleweight jeans that fade fast from brands like Iron Heart, TCB, Naked & Famous, Warehouse, Big John and more.

How to Wash Raw Denim and Why You Should (S01E15)

In this episode, Jake and I talk about denim care and how to wash jeans. We discuss the pros and cons of never or at least very infrequent washing, as well as the different washing methods we recommend.

How To Make Raw Denim Last Longer [Video Guide]

When you wear raw denim for months without washing it, you often wear out the denim much quicker than what you might expect.

After a lot of trial and error, I discovered that I could make my raw denim last longer AND get great fades with this super simple denim care trick.

4 Raw Denim Care Myths That Aren’t All Busted

With raw denim’s spread from niches to masses, several myths about raw denim care have taken hold in the public conscious. As a result, you might be getting really bad advice about how to best take care of your jeans.

This member resource discusses why these 4 raw denim care myths aren’t totally busted: soaking in vinegar, tumble drying, dry cleaning, and the bathtub soak.

3 Popular Raw Denim Care Myths That’re Totally Busted

When it comes to raw denim care, there’s no shortage of false assumptions and myths. In this member resource, I bust three of the most common ones; freezing your jeans, washing them in the ocean, and waiting six months before you wash.

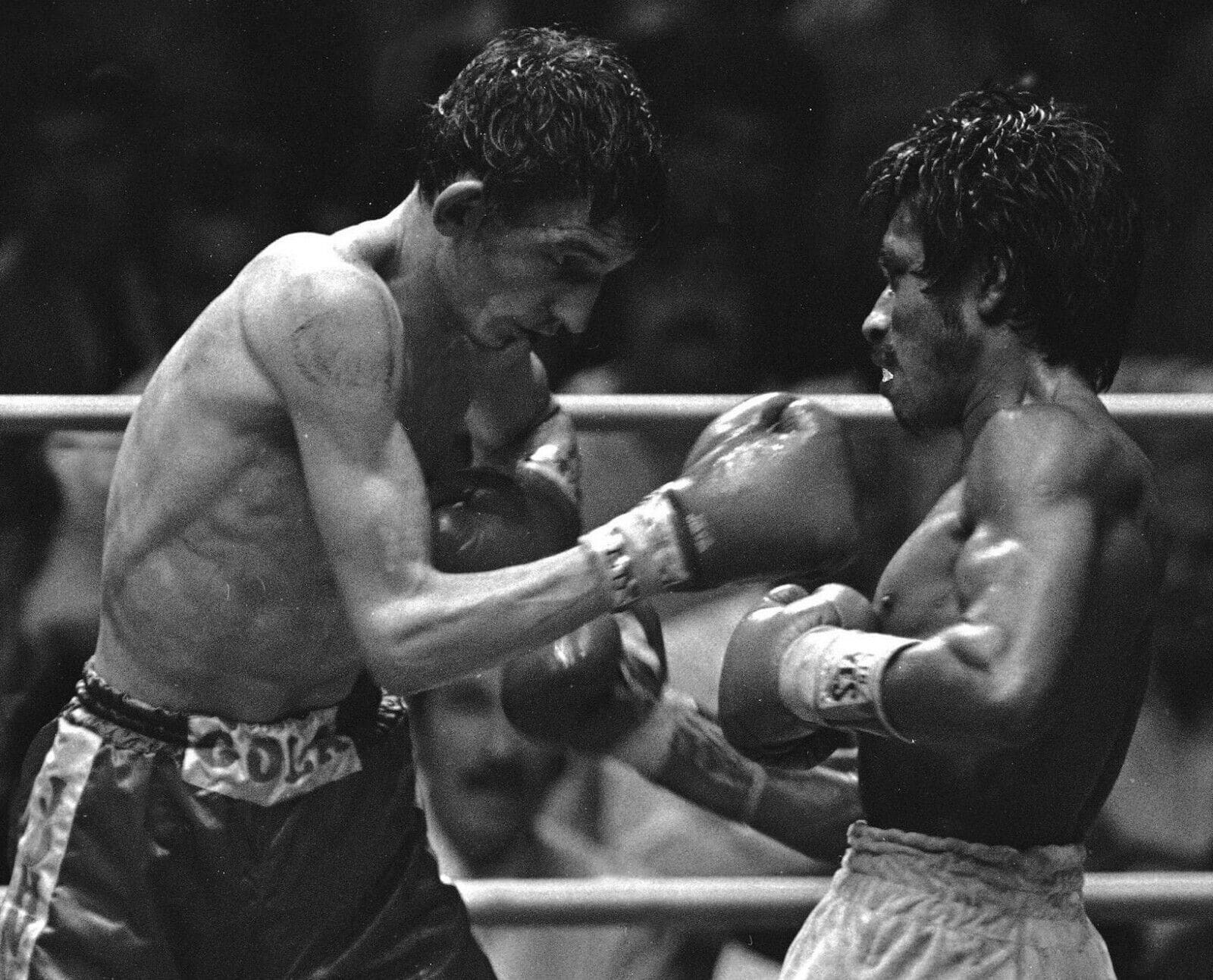

An Overview of the Four Eras Jeans History

When you’re selling jeans, you’re selling history! That’s why it’s crucial to know at least the key facts of the history of jeans when you work with denim and jeans. And that’s what this blog post teaches.

How the Japanese Pioneered Heritage Fashion

In this 4th part of my series about the history of jeans, you’ll learn how the Japanese built a cult around Americana, which evolved into heritage fashion.

How Vintage Denim Became a Thing (… and How It Created Heritage Fashion)

In this history of jeans overview part 3, you’ll learn how vintage denim broke through the mainstream, plus how to tell the story when you’re selling.

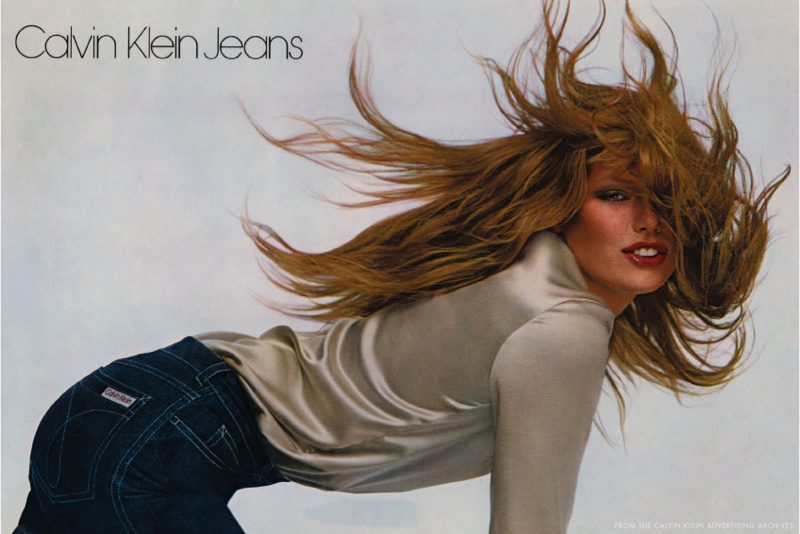

How Designer Jeans Broke Through the Mainstream

In this part 2 of my history of jeans overview, you’ll learn how ‘designer jeans’ broke through the mainstream, plus how to tell the story when you’re selling.

How Denim Is Made: Fabric Finishes

This final episode of my “how denim is made” series discusses how the two kinds of fabric finishes impact the way denim looks and behaves. The trick is to use this knowledge to your advance a make it part of the story you tell.

How Denim Is Made: Weaving

In this fourth episode in the series about how denim is made, you’ll learn how denim is woven and why denimheads prefer shuttle-loomed denim.

How Denim Is Made: Indigo Dyeing

In this third episode in the series about how denim is made, you’ll learn about natural and synthetic indigo, and the differences between rope dyeing and slasher dyeing.

How Denim Is Made: The Spinning Process (… and Why I Prefer Ring-Spun Yarn)

In this second episode in the series about how denim is made, you’ll learn how yarn is made in the spinning process of denim production. I also discuss the pros and cons of ring spinning vs. open-end spinning and why denimheads prefer ring-spun denim.

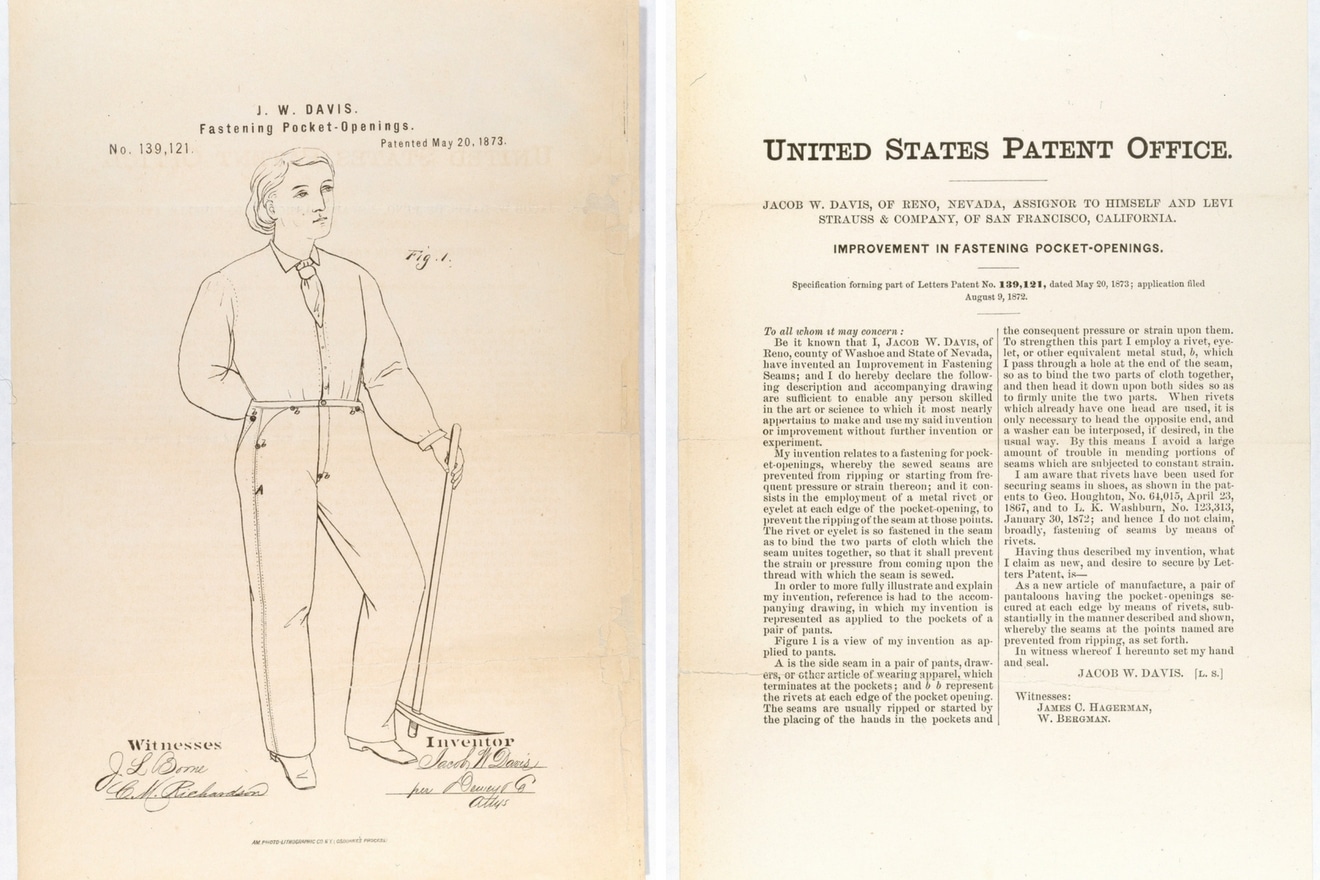

The Reason Why Jeans Have Rivets [Video Guide]

Rivets are a key defining feature of blue jeans. They were introduced in the early 1870s as a simple and durable solution to an urgent need for durability. In this video guide, I explain the origins of rivets.

The Innovative Features That Define the Modern Jean

When you know how the defining features have evolved, you can build better narratives about the jeans you’re selling by putting them into a bigger picture.

Purchasing Power: Labels That Highlight The Pedigree of Your Jeans

When we look for new jeans, there’s much more than the colour and fit to take into consideration. In this article, I’ll be looking specifically at the labels that appear on premium denim, and the semiotic and semantic power that such labels carry.

The Defining Features That Help Us Keep Our Jeans Up

In this free guide, I will look at all of the features that jeans makers use—and have used—to make our jeans fit right, and more importantly, not fall down while you’re wearing them.

BUY OUR BOOK ABOUT MENSWEAR

Support us as the author and buy your copy of the book by clicking the links on this page.