This Encyclopedia entry is a must-know term. Learn more in our Denim vocabulary.

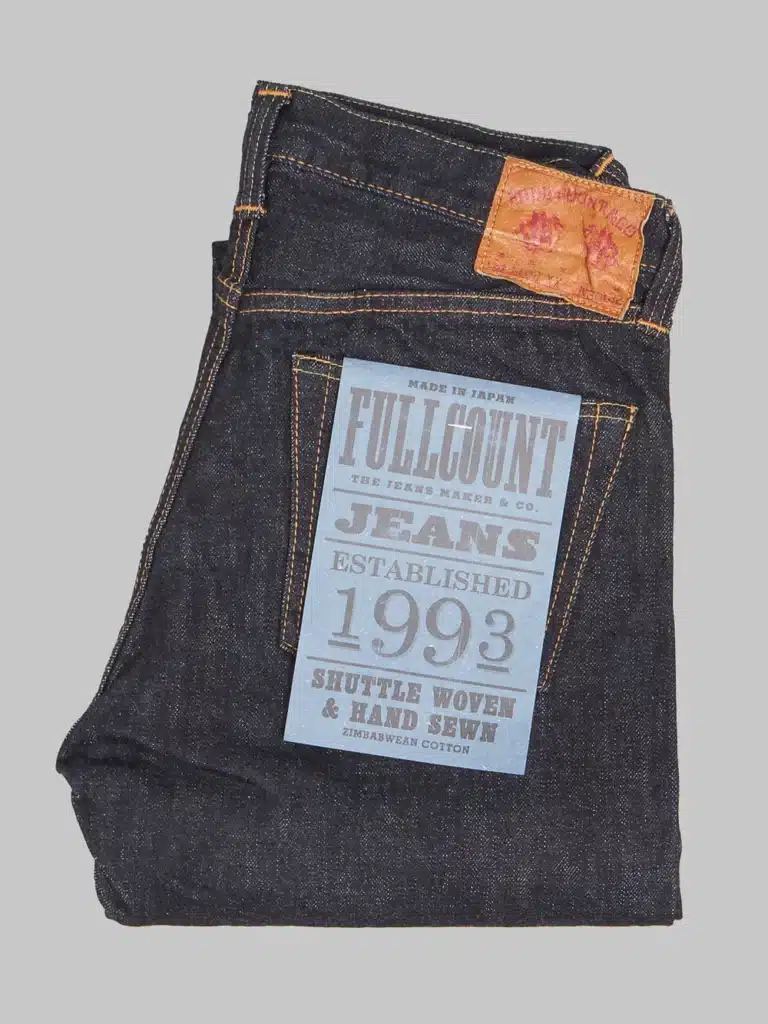

‘Selvedge’ is the name for the higher-quality, harder-to-produce type of denim that is typically sold and worn unwashed.

You can spot it on the cuffs of jeans. The selvedge in denim is usually white and often has a coloured yarn in the middle. If that yarn is red, it’s called ‘redline’ selvedge, which you can read more about here.

This technical term actually ought to be spelled ‘self-edge.’ The term refers to the self-finished edges on each side of fabric woven on shuttle looms. These edges don’t fray or unravel.

But why is it more expensive than ‘normal’ denim? And is selvedge denim better?

Hand-Picked Must-Haves and Essentials

Sorry to interrupt your reading but we’ve found these products that we really think you should take a closer look at!

Support us when you shop: We earn a small commission when you buy from these merchants.

How selvedge denim is made

There are two ways to weave denim: with or without a shuttle. Weaving with a shuttle is the old school way.

The shuttle is essential; it threads the weft through the warp shed. As the weft is continuously passed back and forth, the edges of the fabric are self-finished, which is why it’s called ‘selvedge.’ This tightly woven and durable edge can be included in the garment without additional processing.

Looking for the Biggest Bang for Your Buck?

Great selvedge isn’t necessarily expensive. If you’re looking for big value for your money, your safest bets are: TCB 60s Regular Straight (€180), Japan Blue J301 ($185), and Sugar Cane 2009 ($195).

Hurling a shuttle back and forth is a relatively time-consuming process that creates a bottleneck in terms of production speed. So, when they need to weave faster (and cheaper), denim makers use shuttleless weaving machines.

Shuttleless weaving is most commonly done with a projectile loom. Instead of a shuttle, a small metal device that looks like a bullet (hence the name) carries the weft across the shed.

This is called weft insertion, and it creates frayed edges at each side of the fabric that have to be cut off before it can be sewn into a pair of jeans.

You can read much more about weaving here.

Why Is Selvedge Denim More Expensive?

Shuttleless looms usually weave at least four times faster than shuttle looms. And because the weaving frame can be widened, production capacity is up to 10 times higher.

In other words, you can get 10 times as much denim per hour when it’s not selvedge, and that obviously affects the price.

The fact that all shuttle looms are old and need a lot of care and maintenance to keep them weaving is another important cost factor.

Selvedge Masterlist Top Three Jeans

The list of our favourite Japanese selvedge jeans is long, but at the very top of it, you’ll find: Iron Heart 634S, Samurai S710XX, and ONI 622ZR.

Is Selvedge Denim Better?

Denimheads and industry people all agree that selvedge denim fades ‘better’ than non-selvedge denim.

The slower pace of shuttle looms puts less tension on the yarn. And it’s a fact that shuttle looms tolerate more slubs in the yarn, which add character to the denim. Shuttle-loomed denim is also naturally softer.

Together, this gives ‘better’ fades (subjectively speaking). And that’s why enthusiasts prefer selvedge denim.

But in terms of durability, selvedge denim isn’t significantly better than non-selvedge denim. The fact that denim is selvedge doesn’t mean it will last longer!

However, since most selvedge denim jeans are not washed in a factory, they would probably last a little longer in theory.

But—and this is super important—when you don’t wash your raw denim garments, they’re not going to last as they could if you washed them.

Want to Build a Better Wardrobe?

Denimhunters is a knowledge portal for denim enthusiasts and newcomers. Launched in 2011 as a pioneering denim blog, we’re a trustworthy source of denim knowledge and advice.

Our buying guides to well-made menswear help you build a timeless and adaptable wardrobe of carefully crafted items that’re made to last. Start your hunt here!