4 Defining Features of Jeans That Originally Served Practical Purposes

Shoes have soles and uppers. An oxford shirt has a button-down collar and a basketweave fabric. A leather jacket has got, well, a shell made from some kind of leather. Everything’s got a combination of essential features; defining characteristics that make it what it is. The same goes for blue jeans.

There are around a dozen of the features that define the archetypical pair of five-pocket blue jeans. Not all jeans have five pockets, and not all are made from indigo-dyed denim. But the defining features are the basis for any trouser that is categorised as jeans. These are features that have historically distinguished jeans from other trousers.

In this series about the defining features of jeans, I look into the stories behind them. Why were they there in the first place? What function did they serve? And how has their purpose changed over the years? I will address the features based on their original intent.

The topic of this first episode is the features that originally served the purpose of durability and practicality. That includes rivets (and bartacks), the pockets, the seams and stitches (which you can learn more about here), and the denim fabric.

Some of these features have more than one purpose today. Most of us don’t really need our jeans to be durable or practical; we don’t rely on the rivets for durability, and some women’s jeans have ‘fake’ pockets. But, because the features have come to define the garment, they’re still there.

The three episodes in the series about the defining features of jeans focus on:

- Features that make jeans durable and practical (this episode)

- Features that help you differentiate one brand from another

- Features that make jeans fit and add support

Rivets: The Original Defining Feature of Jeans

Jeans have been around for centuries. They were made as workwear and served a practical purpose: to be durable and functional. That’s why they were made from denim; a durable, versatile and inexpensive fabric. It’s why the pockets were placed for easy access. It’s also why the stitch count is high, which makes the seams strong. And it’s why they featured reinforcements in places that are prone to tear.

Levi Strauss & Co. is rightfully accredited as the creator of blue jeans as we know them today. Not because they invented work pants made from denim—they’d been around since before Levi’s got into the business—but because they were the first to use copper rivets as reinforcement.

In my opinion, the most important feature of blue jeans is the rivet. Without it, jeans probably wouldn’t have become what they are. Riveted jeans are the result of an urgent need for durability, combined with a little creative thinking.

The rivet was a pragmatic solution to a problem faced by wearers and makers; miners’ and workers’ pants would tear at the pocket corners and other points of strain before the garment wore out. Unlike today, the most important buying criterion was that clothing would last. And in those days, you wouldn’t just drop by the mall or something to get a new pair whenever your pants ripped.

In January of 1871, a tailor of Latvian descent from Reno, Nevada found a simple and elegant solution to the problem. His name was Jacob Davis, and his solution was to hammer copper rivets onto the places where the pants he made would often tear; at the pocket corners and the base of the fly. The rivets kept pockets and seams from bursting when miners and workers were doing heavy work. They also differentiated his pants from his competitors’, which meant they became an instant success.

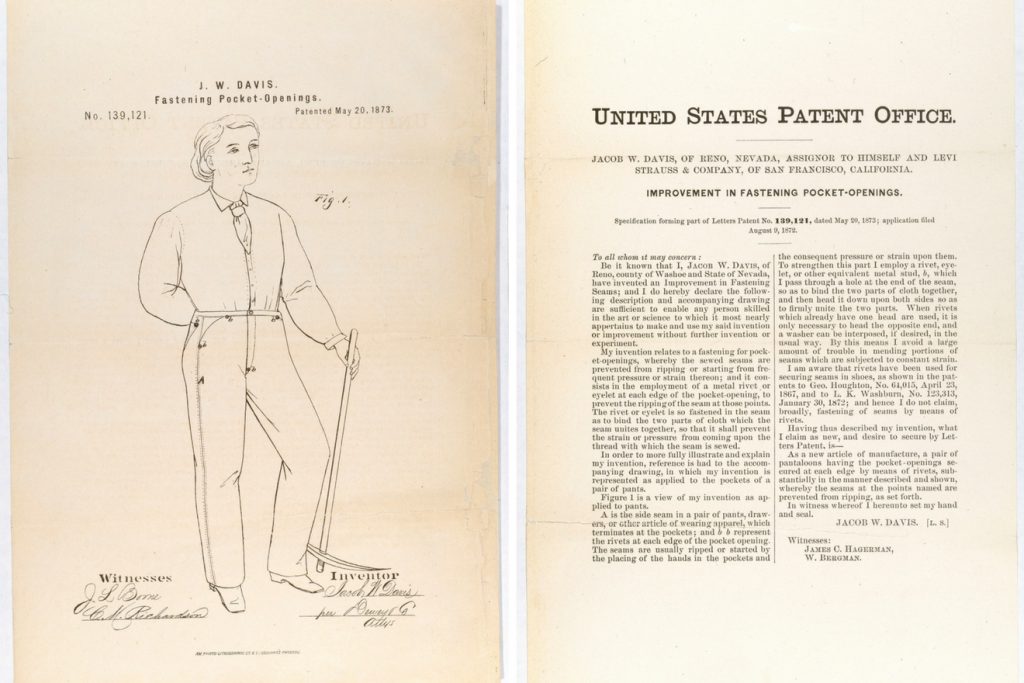

As rivals began imitating his riveted jeans, and as the serial inventor he was, Davis knew he had to patent his idea. But he didn’t have the $68 that a patent cost (remember, that was a lot of money back then). He proposed a partnership with one of his fabric suppliers from San Francisco in 1872. You guessed it, that supplier was Levi Strauss, born “Loeb” in Bavaria, Germany. Strauss paid for the patent and Davis then moved to San Francisco to oversee the production of his design.

They filed the patent application in August of 1872, and were granted the patent a year later, on May 20, 1873—which is now considered the official birthday of blue jeans. Contrary to trademarks, patents expire. For US patents issued before 1995, the term of the patent was either 20 years from the earliest filing date or 17 years from the issue date, whichever is longer.

That meant the patent for the “improvement in fastening pocket-openings,” #139,121, expired in 1890. However, the patent was reissued in 1875, which meant it would expire in 1892. But that was enough time for Levi’s to get a head start on their competitors.

For the 19 years Levi’s had the patent for rivets, competitors developed alternative strengthening methods. None were as simple, durable or elegant as the copper rivet. When the patent expired, rivets became a standard feature of jeans from all brands. By that time, Levi’s had already been established as the originator of riveted workwear, and the brand name even became synonymous with ‘waist overalls,’ as jeans were called back then.

That’s how rivets became a defining feature of blue jeans. But while most jeans still have rivets today, they mainly serve an ornamental purpose; most jeans never see any heavy-duty action that requires the durability that rivets offer.

Instead, rivets remind us of the values of the garment; a romanticised idea of hard work and tough guys, rebels and the American dream. And it sells. But it’s the values that jeans connote we want, not the actual back-breaking work that the original wearers did.

Now, rivets are not the only way of reinforcing blue jeans that’s become a defining feature. Even after the patent had expired, some makers used alternatives to rivets. The most common one is bartacking.

Bartacks and the Problem With Rivets

While using rivets as reinforcement is a quite brilliant solution, rivets do have drawbacks. The pointy ends of them that face outwards have a tendency to scratch whatever they get in close contact with. Especially if they’re the old-fashioned kind that’re made with a rivet that is “punched through” the fabric from the inside and fastened with a burr on the outside. When the rivet is too long and cut off, it gets particularly scratchy.

Bartacks don’t scratch. A bartack is a tight row of zig-zag stitches that is repeated over and over itself. “Bartacks are made on a special sewing machine,” I’m told by denim designer, Christina Agtzidou. She adds that they’re usually sewn horizontally to the grainline (the warp) of the fabric. Vertical bartacks might create tearing issues when the jeans are washed, especially for lightweight and stretch denim.

But bartacks are also a little less durable than rivets—at least they were in 1871 when sewing technology was still in the early stages of its development. As sewing machines evolved, bartacks became a viable option. It’s a cheaper solution which made it the standard for price-competitive workwear.

When Lee went into the ‘western wear’ jeans business in 1926, their Cowboy Pants featured both arcuate back pocket stitching and copper rivets. In other words, they looked exactly like Levi’s jeans. While the arcuate stuck around until Levi’s trademarked it in 1943, the back pocket rivets and the one at the based of the fly disappeared by the 1930s to prevent cowboys from scratching their saddles. They created the most recognised use of bartacks with the X-bartack. (Quite simply, two bartacks are sewn onto the back pocket corners at 45° angles, which creates an X.)

Even Levi’s gave in to customer demand in 1937 and made the riveted back pockets scratch- proof by concealing the rivets under a layer of denim. By the mid-1960s, the back pocket rivets disappeared entirely on Levi’s 501 jeans. Launched in the same era, the youth-targeted Orange tab line didn’t feature rivets at all!

Another alternative is the scratch-proof rivets that you find on Wrangler jeans. Instead of using a punch-through rivet and a burr, Wrangler’s rivets had a flat front, known as double-cap rivets. But rivets weren’t the only defining feature that made jeans durable.

The Denim Fabric: What Truly Makes Jeans Durable

I sometimes forget that the most practical of all the defining features of blue jeans is the denim fabric itself.

It’s a cotton twill that traditionally has an indigo-dyed warp and a white weft. Its name is an Anglicised version of “serge de Nimes,” which was a denim-like fabric from southern French that became popular in England in the 1600s.

While denim’s exact origin is unclear—we only started caring about it in the 1900s, centuries after its invention—there’s no doubt its popularity to a great extent is caused by its hardwearing capabilities.

Denim’s blue colour is one of the reasons it’s so durable. Indigo has been used for millennia around the world. It was the colour of royals, which made it popular among the proletariat. And indigo is very suited for garments that see a lot of wear and tear. Especially when new, crispy and dark, indigo-dyed denim repels dirt and water. And the fact that it’s warp-faced means that only one set of yarn needs to be dyed, which means less dye is required.

The unique dyeing technique used to dye yarns for denim results in the ring effect. And that’s what makes it fade the way it does. As jeans transitioned into the realm of fashion, an industry that makes pre-distressed jeans to mimic natural wear and tear has been spawned. That means indigo dyeing has become a matter of aesthetics rather than practicality. You can learn much more about how denim is made in my blog post series on the topic.

Another defining feature that used to be there for practical reasons is the pockets.

How Pockets Went From Being Practical to Shaping Behinds

Because jeans were originally made as workwear, form was second to function. And because they had to be inexpensive, the design was relatively straightforward. One example of that is the pockets.

Jeans pockets needed to be sturdy and easy to access. That why the back pockets were placed further out on the hips than what most are today. And it’s why they’re pointed, which makes it easier to reach what was in it.

When we talk about jeans, we usually talk about five-pockets. You’ve got two curved inset front pockets with pocket bags typically made from unbleached twill. Then you’ve got a small patch pocket that’s half tucked into the left front pocket. That one’s most commonly referred to as the coin pocket, but denim expert, Mohsin Sajid argues it’s actually a match pocket, as in a pocket to store matches—which makes a lot of sense when you think of the original wearer of jeans as a miner who uses candle lights down in the mineshafts. And lastly, you have two pointy back pockets that are the stitched-on kind, also known as patch pockets.

Anything that has less than five pockets, or an arrangement that’s not three in the front and two in the back, is going against the unwritten rules. And it’s going to get noticed. But blue jeans didn’t always have five pockets; they originally had four. This is where confusion often sets in—which is the fifth pocket?

Contrary to what seems to be popular belief, the fifth pocket is not the coin pocket. That’s been there since the dawn of blue jeans. It is, in fact, the left back pocket that’s the fifth pocket. It was added around the turn of the nineteenth century, probably due to popular demand, and most notably the 501 got it’s second back pocket around 1901.

Over the years, designers have experimented with the number, shape and placement of jeans pockets. You might remember that Diesel made women’s jeans without back pockets around the turn of the millennium. The design of Levi’s Engineered—penned by a fellow Danes, Rikke Korff and Christine Detlefsen—were famously based on the pre-five-pocket 501, complete with one back pocket and twisted seams. And these days, high-stretch women’s jeans sometimes have fake front pockets, meaning they don’t have a pocket bag.

The purpose of pockets has changed from a matter of practicality to how they look. And especially the back pockets are important for how a pair of jeans visually present themselves; as we’ve learned from this article, denim designers put a lot of attention on pocket placement as it shaped the wearer’s behind.

All of that being said, there are certain unwritten rules designers need to follow. Adding slit front pockets to a pair of jeans would most likely make them cross the barrier into no man’s land between chinos and blue jeans.

On the Hunt For Raw Selvedge Jeans?

Launched in 2011 by Thomas Stege Bojer as one of the first denim blogs, Denimhunters has become a trusted source of denim knowledge and buying guidance for readers around the world.

Our buying guides help you build a timeless and adaptable wardrobe of carefully crafted items that are made to last. Start your hunt here!

Share