Adriano Goldschmied, Stefano Aldighieri and Giovanni Petrin Tell the Story of Pre-Washed Jeans

This blog post is sponsored by Tonello, one of the Denimhunters Academy crowdfunders.

Jeans are loved around the world for numerous reasons. There’s the values we associate with them. There’s the durability and comfort. The (almost) endless ways to style your jeans.

The biggest allure of jeans, though, is how they evolve with you as you wear them. How they become ‘yours’ as they document your lifestyle and how you’ve worn them. How they’re the most democratic garment around, but also the most individual.

The catch is that it takes time, patience and hard work (sometimes quite literally) to achieve that desirable lived-in look.

The solution is what we called pre-washed or pre-distressed jeans. The kind that looks like they’ve been worn for years when you buy them. And the methods and technologies used to create these effects are what’s called ‘garment finishing;’ an area of the denim industry that’s been constantly evolving since it emerged in the 1970s.

Mapping the History of Pre-Washed Jeans

But how did it all begin? What was the inspiration? What kind of technology did they use? And how has the industry evolved?

To find out, I’ve talked to three Italian gentlemen who’ve been part of the jeans business for at least as long as I’ve been alive:

Stefano Aldighieri got into denim in the late 80s, and his resumé includes ‘design director at Levi’s.’

Giovanni Petrin has been pioneering the garment finishing business since it was cradled, most notably as manager of the immensely influential Martelli laundry group for almost three decades.

And then there’s the Godfather of Denim himself, Mr Adriano Goldschmied, who’s the man behind brands such as Diesel and Replay, and, as you will learn, the man who brought one of the most recognised finishing technologies to Italy.

With their help, I’ve identified a handful of eras of the history of pre-washed jeans. But let’s begin at the beginning—before there was such as thing as pre-washed jeans.

Before the Jeans Finishing Industry

Although many claim to have ‘invented’ pre-washed jeans, nobody can tell for sure, Stefano Aldighieri tells me via email.

I would imagine that the first examples of pre-washed jeans were made by costume makers at movie studios when they had to dress western movie actors who couldn’t wear brand new jeans on screen.” A theory that makes a lot of sense.

Brands first pre-washed jeans to get rid of shrinkage, he elaborates. It just turned that out many also appreciated the softness as opposed to the stiff and heavily starched non-pre-shrunk jeans.

People liked the look of worn-in jeans, but either didn’t feel like buying second-hand ones or they were too impatient to age them themselves,” Stefano explains.

As I’ve discussed in my series about the history of jeans, the garment became fashionable in Europe in the late ‘60s and early ‘70s. Inspired by the hippie movement, pioneering Italian brands like Rifle, Roy Rogers, Fiorucci, Bell Bottom, King’s and Ufo began making jeans around that time.

Hand-picked suggested further reading: How Designer Jeans Broke Through the Mainstream

That’s when garment finishing laundries started popping up, “because the jeans needed to be washed,” as Giovanni Petrin puts it.

Customers wanted jeans that already had the desirable lived-in look; jeans with ‘personality’ right off the store shelf. One of the first to pre-washed jeans was Adriano Goldschmied.

The idea of washing jeans came to me almost by accident,” the Godfather of Denim recalls. “I was inspired by the bleached spots that hippies were making on their jeans.”

At first, he made the jeans himself. “I would make a fire under a big pot in my courtyard, and there I would ‘cook’ my jeans,” he remembers.

Adriano quickly realised that washed jeans were much more popular than unwashed ones. “Every day, I had customers lined up outside of my store fighting to get the few jeans that I was able to produce.” This was around 1972.

The First Era of Pre-Washing: ‘The Stone Age’ (70s-80s)

The early ’70s is also when the story of Tonello begins. Working as a specialist in machine maintenance, Osvaldo Tonello would modify industrial laundry machines together with his customers.

In 1975, he built the very first Tonello laundry machine, the RC 60-120. Talk about being at the right place at the right time; the beginning of the washed denim revolution.

Back then, there were only two ways to pre-wash jeans; rinsing and bleaching. It wasn’t until the end of the ‘70s that Adriano brought a new washing technique to Italy, Giovanni recalls. Of course, that technique was stonewashing.

Giovanni was a partner of the laundry that made those jeans for Adriano, and he remembers quite vividly how the story began.

Adriano told us that in Japan he’d seen jeans washed with white stones and that the effect was wonderful.”

Giovanni’s response was ‘no problem,’ believing they could scoop up stones from local rivers. But, when they put the stones in a washing machine together with five pairs of jeans, he quickly realised the mistake.

The noise was loud because of the heavy stones. After 30 minutes, we checked and found the jeans full of holes and the drum of the washing machine completely dull.”

At the second attempt, they used pumice stones with greater success. Tonello’s cylindrical stonewashing machines pioneered this revolutionary change in denim, which Osvaldo’s niece, Alice Tonello—who’s in charge of marketing and R&D at the family business—calls ‘the stone age’ of denim.

The machines would use water and stones only, Stefano explains, and it took a very long cycle to get a properly aged look. Even when you did, the fade would the same all-over the jeans. That changed in the second era of pre-washing.

The Second Era of Pre-Washing: Artisans and Replicas (80s-00s)

After those pioneering years, designers and laundries began experimenting with a more localised abrasion on the jeans.

The goal was to replicate the whiskers and honeycombs of naturally worn-in jeans, but also stains, scratches, cuts and tears, which were created by hand. Tinting, overdyeing and brushing also started appearing at this time.

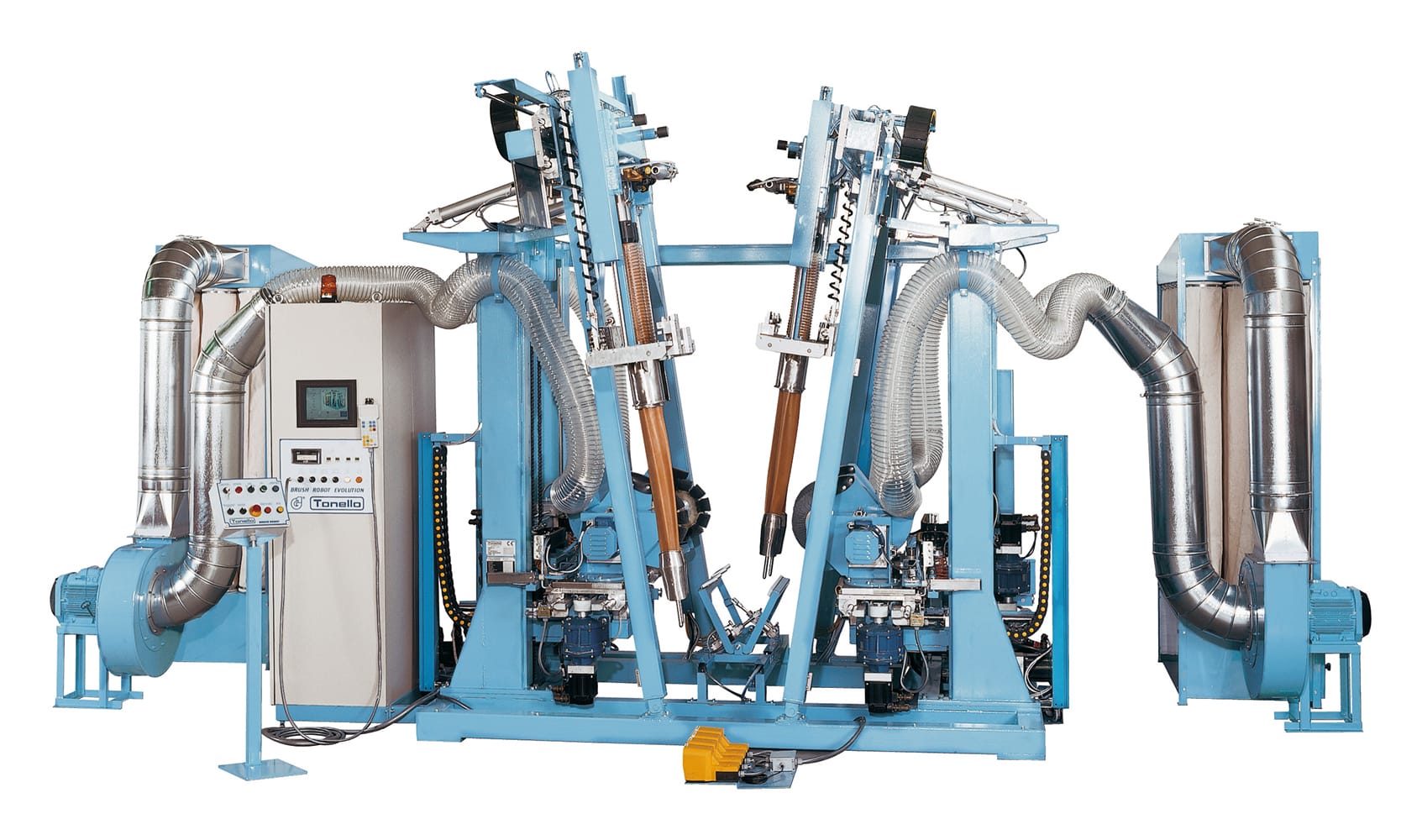

To create local fades, for instance on the thighs, Tonello built the Brush Robot. An automatic machine equipped with big brushes that scrape the jeans. The first Brush Robot was installed at the Martelli plant in Vedelago in 1990. It took about a year of testing before they got the desired effect, Giovanni recalls.

Below is a short clip of the E5 generation of the Brush Robot in action. More recent Tonello developments in this area of garment finishing include the Ecospray Robot and Water Brush.

Another novelty of the ‘80s was less authentic. During a night shift at the Lavanderia Candida in Italy, a worker forgot to open a water valve during a stone bleach. At the trade show in Cologne, Rifle introduced the finish, which became known as ‘marble’ or ‘acid’ washing.

This was also when the now-banned treatment of sandblasting was invented. Inspired by how artisans would sand down wood and iron, it was applied at denim laundries. Yet it was difficult for the workers, and it was hard to find skilled staff, Giovanni recalls.

Similar results were achieved spraying bleaching and oxidising chemicals such hypochlorite or potassium permanganate onto the jeans.

Around 1993-1994, due to a crisis in the Italian textile industry, most of Italian jeans production was outsourced, in particular in Turkey and Tunisia. That’s when Giovanni and his team in Martelli Vedelago made the first hand-scraped jeans using sandpaper.

The first hand-scraped collection was made to celebrate the 25th anniversary of Gap with the Gap 1969 line, designed by Adriano.”

It felt like nothing was impossible, Giovanni argues. In 1996, Martelli created the first mannequins to do whiskers and scrapings on.

All these new technologies changed the look of jeans. Designers and jeans makers focused on recreating vintage jeans and recreate the naturally worn-in look as accurately as possible.

At the same time, retail prices of jeans kept climbing with premium and luxury brands dominating the market. “The years from 2000 to 2008 was ‘the golden age of jeans’,” Giovanni reminisces.

The Third Era of Pre-Washing: Aided by Technology (00s-)

Technologies such as Tonello’s Brush Robots, hand-scraping and more recently laser have massively increased the creative opportunities that designers have. And as the quality of the washes increased, so did demand.

Around the turn of the millennium, there was an exponential increase of technology introduced to the jeans finishing industry. For instance, a bit ahead of the curve, Giovanni and his team made the first attempts with laser finishing around the year 2000, which allows laundries to create any kind of look with minimal quality issues because the operation is mechanised.

In the ‘artistic era,’ only an elite of laundries in Italy could compete,” Adriano argues. With the help of technology, things have changed.

Laundries are becoming cleaner and less wasteful. The introduction of technologies such as washing with enzymes has also dramatically changed how ‘old’ methods like stonewashing are done. And it’s got a lot to do with minimising consumption of resources.

“People are finally starting to realise that inordinate amounts of water are being wasted to process jeans, and the industry as a whole is slowly getting better,” Stefano critically observes.

The adoption of laser technology and ozone processing are probably the biggest advancements, the three experts I’ve talked to agree. Ozone was first used to eliminate redeposition but was later extended to remove indigo with minimal amounts of water.

The ozone technology is a big advantage because we use less electricity, water, material and chemicals; it reduces time, increases efficiency and improves the look of the jeans,” Giovanni explains.

In 2010, laser machines were reintroduced with new equipment and software. “The first samples were shown at Denim PV,” Giovanni recalls, and the industry responded with great enthusiasm. The laser has proved to be one of the most important new technologies in the denim world.

The video below shows Tonello’s Laser Blaze technology in action.

We are witnessing a fundamental shift in how we wash jeans,” Stefano adds. “Even though the goal of a completely water free wash is still out of reach, we are making vast improvements.”

I asked Adriano how the business has changed from when he first started washing the jeans he sold back in the early 1970s:

They literally look like two different planets. In my time, everything was done by hands. Today, the washing facilities are huge. They are changing not only the industry but also the social and economic structures of the countries where they are.”

The Future of Jeans Pre-Washing

The denim industry, particularly the garment finishing part of it, hasn’t always been the cleanest. In the 2010s, laundries and their suppliers, such as Tonello, have become increasingly engaged in the search for more environmentally friendly technologies that respect not only the environment but also the workers.

In the 00s and 10s, we’ve seen the ban of sandblasting; enzymes have almost completely eliminated the need of pumice stones; we are close to banning potassium permanganate; resins are now available with zero formaldehyde content,” Stefano summarises.

Apart from environmental motives, automation has also helped reduce the costs of the final garment. But how do laundries maintain production efficiency and the aesthetics of the garments while respecting increasingly stringent regulations?

The simplest solution would be to not finish the garments at all. Or buy second-hand. But not all consumers want raw denim jeans; and with second-hand jeans, there’s the issue of finding a pair that fits. The second best solution is to reduce or even discontinuing the use of harmful procedures.

The most important challenge is how to produce with the lowest possible environmental impact, but also change the working conditions,” Adriano argues. “This is a fight humanity cannot afford to lose,” the veteran designer warns.

Innovative Laundry Tech from Tonello

Tonello has always been a (co-)creator of ideas, a problem solver, a partner for the denim industry; not merely a supplier.

In 2013, Tonello introduced the ECOfree, initiating a washing revolution where bleaches and stones are replaced with ozone.

In 2015, they launched NoStone, an innovative abrasive drum, developed in collaboration with Levi Strauss & Co., which creates a similar result as stonewashing but without the stones. Tonello declared it the end of ‘the stone age’ of denim.

The latest innovation is the ECOfree 2 that can treat garments with ozone in both water and air. It enables new aesthetics, lower consumption of electricity and water, shorter processing times, reduced purification costs and the absolute safety for the operator and for the consumer.

In the future, laundries are going to look more like high-tech laboratories with people in lab coats and machines replacing many of the traditional steps used today, Stefano predicts. Cleaner, more efficient, less dependent on water.

The greatest opportunities are in the exploration of the potential applications of the new technologies we now have available and to truly improve our process and the environmental impact,” Stefano concludes

In his latest research report, Giovanni agrees that new technology and AI will continue to change the textile industry.

When I asked Adriano about the future of the jeans laundering industry, he told me he envisions how robots, sophisticated machines, and AI design software will be working together to create great products in a world where people are happy.

On the Hunt For Raw Selvedge Jeans?

In the blog post How Jeans Are Made: Pre-Washing and Pre-Distressing you can learn more about pre-washing and garment finishing.

To stay up-to-date with what they’re doing over at Tonello, you can follow them on Instagram and Facebook.

Launched in 2011 by Thomas Stege Bojer as one of the first denim blogs, Denimhunters has become a trusted source of denim knowledge and buying guidance for readers around the world.

Our buying guides help you build a timeless and adaptable wardrobe of carefully crafted items that are made to last. Start your hunt here!

Share

Fantastic article !!!

Highly recommend for the people who works on this industry eager to learn how & who started this amaizing bussines.