How Livid Are Keeping No Secrets About Their Supply Chain

Whenever we buy a piece of clothing, like a pair of jeans, we participate in a chain of events with far-reaching consequences.

As consumers, we often only see and engage in one of the final steps of said chain: the exchange between vendor and customer. Behind this step, there is a long and often hidden journey that brings the garment to you.

How often have you stopped to wonder who made the clothes you’re wearing, where the materials have come from, or how they were procured?

When brands have transparent supply chains, we can clearly trace the journey our clothes make, and the people involved in making them. But more often than not, this chain is far from transparent.

Sure, if you look on the care label, you might see that the garment was made in Japan, or the USA, China, or Bangladesh. When it comes to premium jeans, you’ll sometimes be lucky enough to know in which mill the denim was produced and how it was dyed. But even with this information, you’ve only dipped your toes into a sea of information surrounding the jeans.

Fashion brands have often kept their chain of supply a closely-guarded secret for a variety of reasons.

Nobody wants to advertise that the clothes you buy cheaply were made in East Asian sweatshops. Even more significantly, brands often have close, established relationships with suppliers that have taken years to develop. By opening up their supply chain, they run the risk of their competition swooping in to undercut them.

“Where are these jeans made?”

With the focus shifting towards sustainability in fashion, and consumers becoming ever more aware of the processes that bring garments to where they buy them, Livid are making their supply chains transparent to their consumers. In their latest book, Fades of Indigo III, they explain exactly what processes goes into creating a pair of their jeans.

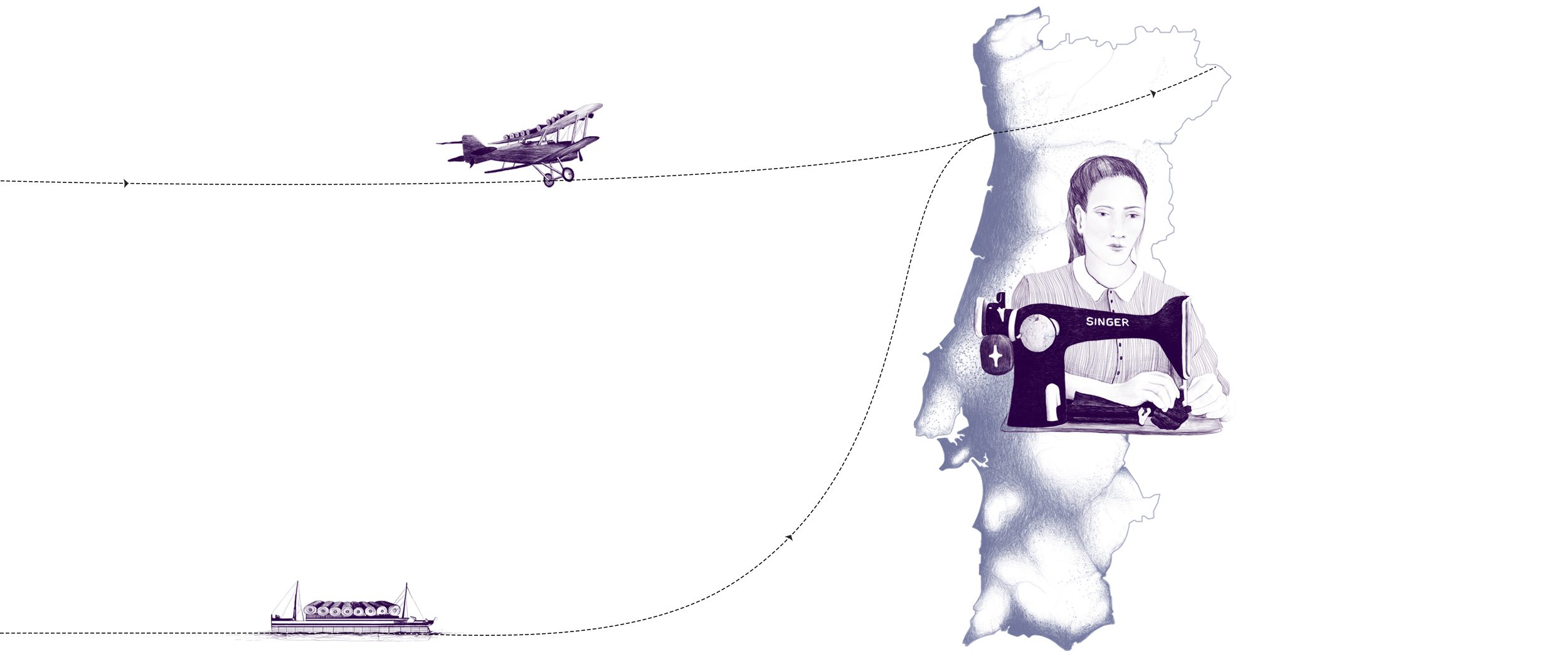

From their inception in 2010 as a one-man-one-machine operation in Trondheim, Livid have held care of production as paramount to their business. Having come a long way since the days when Jens Olav would cut and sew every pair of jeans from his workshop, Livid have outsourced the majority of their production to factories in Portugal, like Vieira & Faria.

Vieira & Faria holds a special place in our history, as they were the very first manufacturer of a pair of Livid outside of Norway,” explains Jens Olav. “It’s a family business in the real sense of the word, with the whole family at work all the way from management to attachment of buttons.”

Jens Olav makes no secret that the decision to move production to Portugal was done in an effort to maintain the growth rate of their production whilst keeping costs down.

Of course, there’s something special about owning a pair of selvedge jeans that bear the label ‘Made in Norway’, and that’s to do with nation branding; the fact that the assumptions of quality or craftsmanship that are associated with a country – embodied by the desirability of USA or Japanese-made denim.

However, having garments produced in one country or another does not guarantee quality. A garment made by a highly skilled seamster in China will fit better and probably last longer, than a poorly sewn garment from the USA.

It’s About More Than Craftsmanship

For many brands, there’s also an ethical aspect to consider as well when they choose where to make their garments.

Livid could have easily outsourced their jeans production for a fraction of the price to a factory in China or Bangladesh, where the working conditions and rights of workers have often been mired in controversy. Except they didn’t even consider doing so.

They were—and still are—committed to working with genuine and honest people. By outsourcing to a family-owned and run business, Livid can put complete trust in the operation, knowing their jeans are being sewn in a safe and fair environment.

Livid still produce to-order jeans in their Trondheim workshop, but the small production runs and cost of having it produced in Norway is reflected in the price, at €235 a pair.

“Why are these jeans so expensive?”

It’s a question you’ve probably asked at some point. Why would you pay €180 for a pair of jeans Portuguese-made Livid when you can buy a pair for less than a third of that at any fast fashion retailer?

By opening up their full manufacturing process, from harvesting the cotton to attaching rivets to their jeans, Livid aim to demystify their manufacturing process.

By candidly showing everything from sourcing to production, and their choice to ensure every step is done so ethically, Livid endeavours to justify the price tag on their jeans.

You see, if you factor in the transportation of materials and garments across the globe, and the fair wages paid to every person involved at every step, suddenly €180 doesn’t seem like an outrageous price for a quality garment.

Now think about that €50 pair of jeans at a mass-market retailer. Of course, higher production runs mean that costs can be driven down, but consider the factories they use to sew their garments and conditions that their workers must endure in order to bring you a garment at such a low price.

As Kristoffer Dagslott, Livid’s CFO, and incidentally their first customer, puts it:

I feel ill towards the hundreds of hands generally involved in the production of a single garment, only to be labeled as expensive by someone without the big picture.”

Sharing Is Caring

Livid are not the only denim brand that gives their customers a glimpse into what goes into creating a pair of jeans—Nudie Jeans also provide a ‘production guide’ online.

But by allowing customers—and competitors—to explore the countries of origin of their various products, Livid are certainly leading the way by going into extraordinary detail about every step of their production process, starting with the harvesting of cotton right through to the retailer.

The overall reluctance of brands to show consumers—and the industry—their supply and value chains gives strength to the idea that designers don’t always know where the garments they’re making come from.

This idea is both true and false.

In fast mass scale fashion, designers can produce their designs irrespective of where, or how, their designs will be made real. Brands that engage in this model understand that these garments will only be desirable for a single season, and so aim to source and produce them as cheaply and quickly as possible.

In contrast to fast fashion, considered design takes each phase of the clothing supply chain into account. The fact that brands like Livid and Nudie can account for, and a proud to share, each step of their chain shows their consideration for the materials used and their impact, the production and the livelihoods of the workers who make them.

To bring into perspective the level of dedication and detail that Livid have put into revealing their manufacturing chain, consider the complexity of their supply chain:

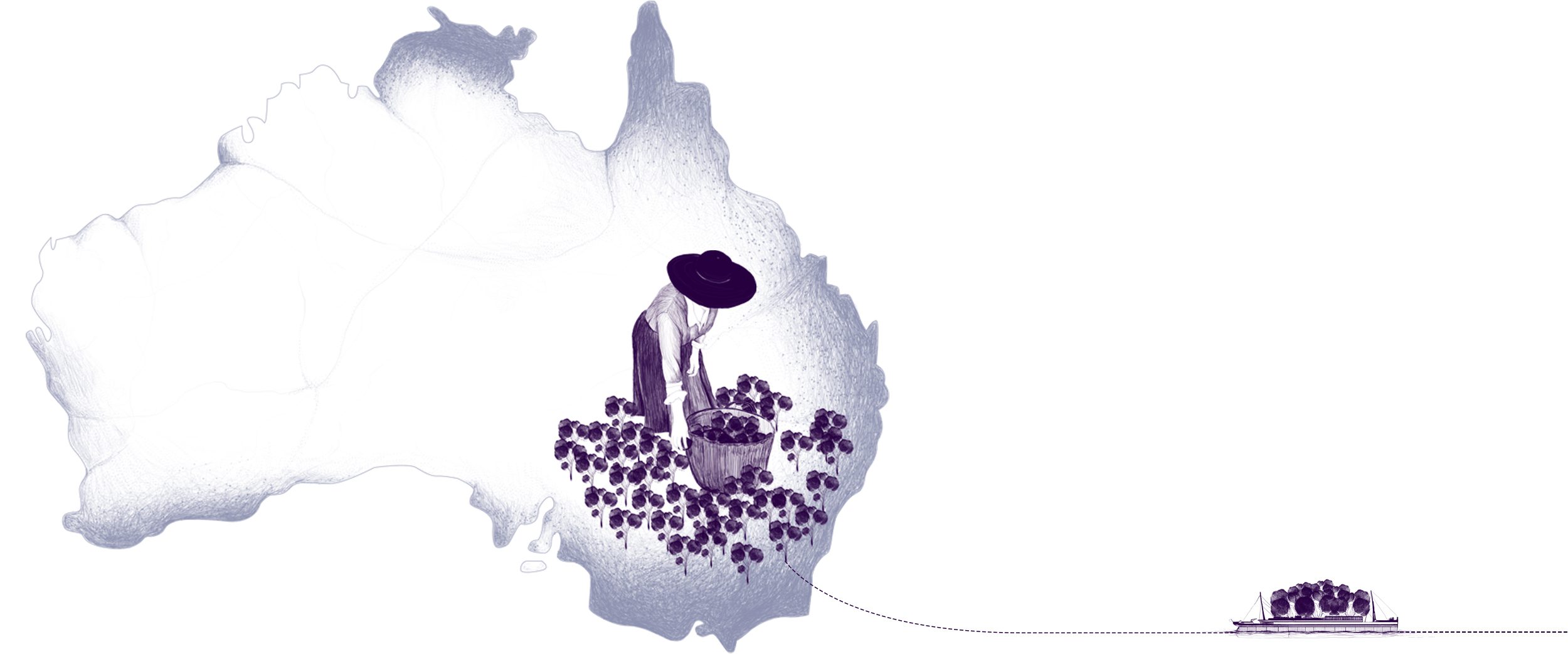

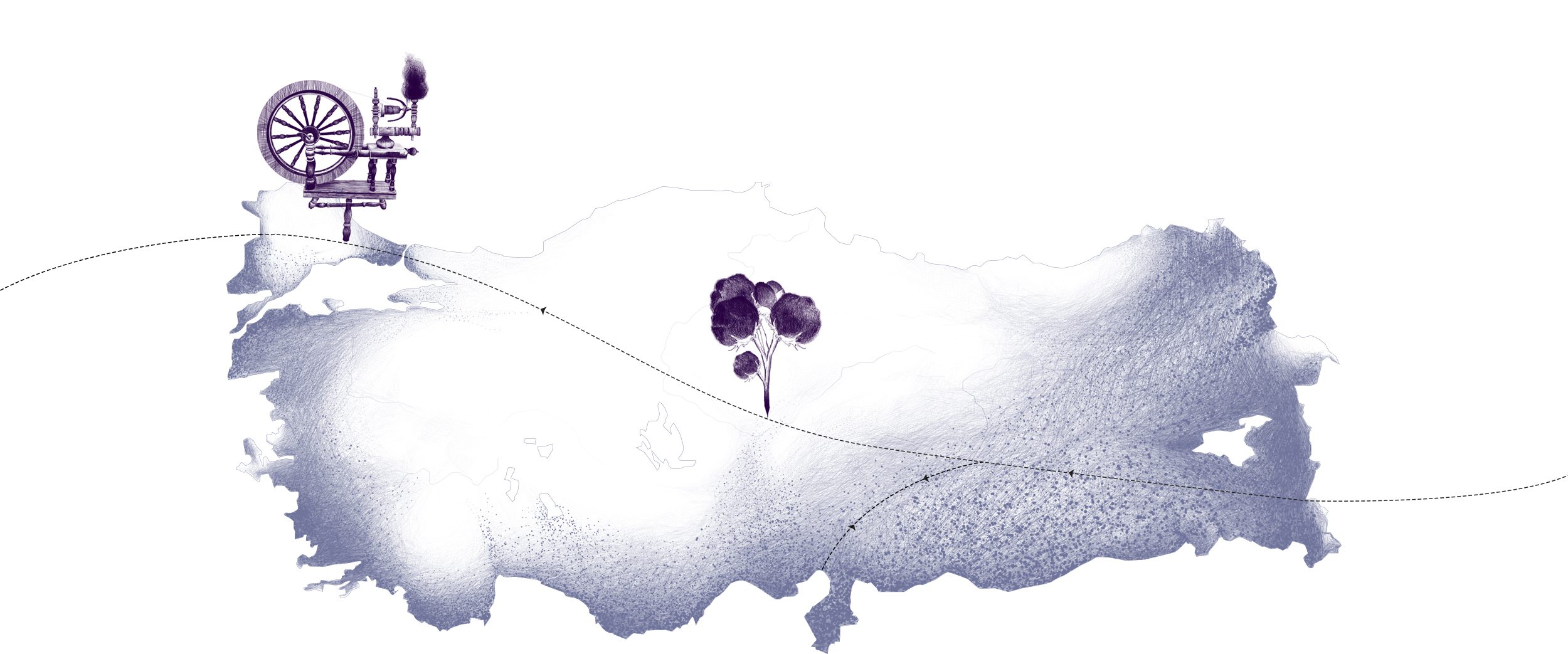

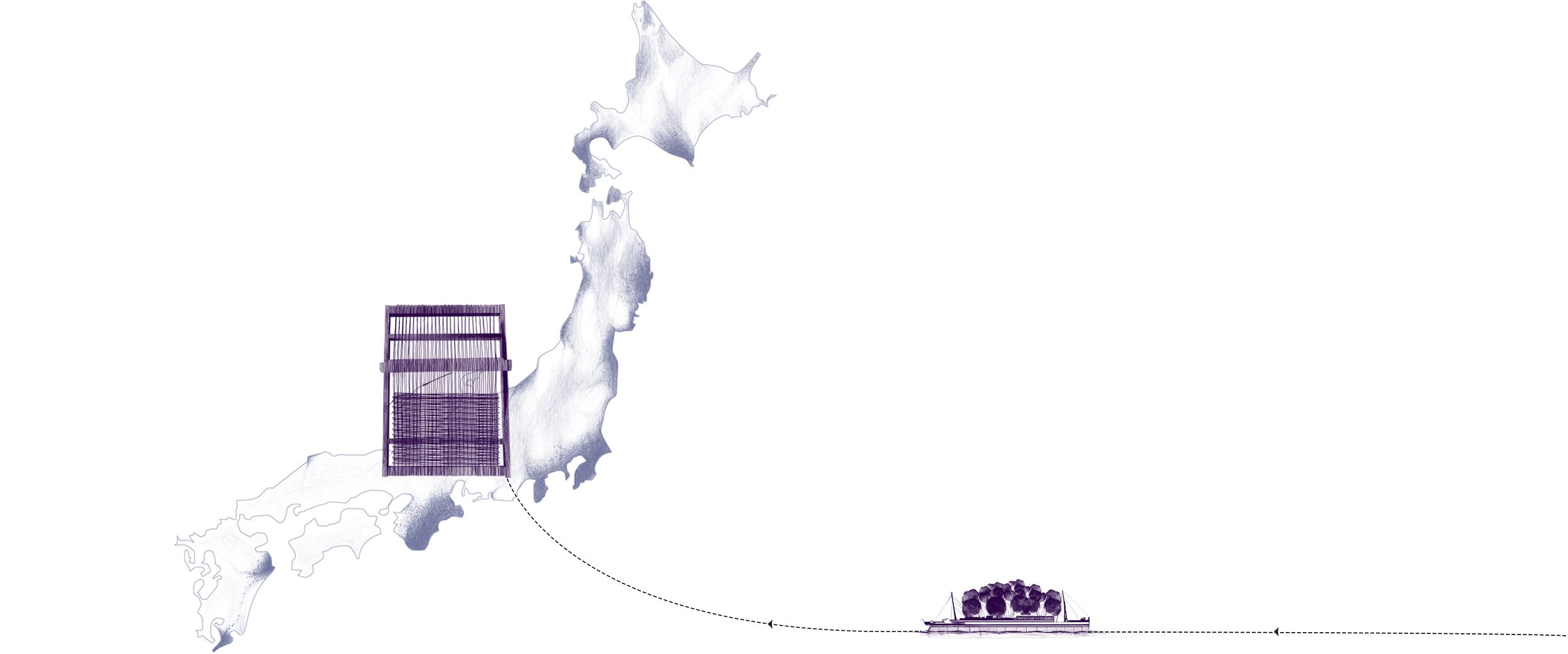

Raw cotton from a wide range of countries such as Zimbabwe, the US and Australia is shipped to Japan for spinning. In Japan the yarns are spun, woven and dyed at a wide range of different facilities, before it is shipped on to Portugal for cutting and sewing.

Tracing information in a global supply chain can be a difficult process and keeping track is far from easy:

Our take is that we feel it is better to share the information we do have,” explains Kristoffer, “instead of not sharing it because we don’t know enough. Our transparency site is just launched, and we view it as only as the first step. We are excited to make it an embedded part of our identity and way of doing business, and we will always strive to improve and expand on the information available on the site.”

Shopping As A Political Act

Today, people choose brands not only because they like the clothes they make but also because of the values they endorse.

Whether it’s because you care about the rights of workers around the world, the impact that your consumption has on the environment or a desire to support your local economy, you invariably take in these into consideration when settling your loyalty to a brand.

That’s why people ‘buy American,’ or organic food, or sustainably sourced clothing.

If demand for sustainable products increase,” explains Kristoffer, “the production of such products will follow.”

And consumers of sustainable products will want proof of their sustainability because they care. Brands like Livid are paving the way for others to follow, and they will because their customers will demand it.

Livid’s transparency is empowering you as a customer to understand the process it has taken to bring you that pair of jeans you pick up in a store. Their transparency is also empowering you as a salesperson with information.

The next time a customer asks “why are these so expensive?”, you’ll be armed with the answers to show that, taking into consideration all I’ve talked about above, their price matches their value accordingly.

On the Hunt For Raw Selvedge Jeans?

Launched in 2011 by Thomas Stege Bojer as one of the first denim blogs, Denimhunters has become a trusted source of denim knowledge and buying guidance for readers around the world.

Our buying guides help you build a timeless and adaptable wardrobe of carefully crafted items that are made to last. Start your hunt here!

Share