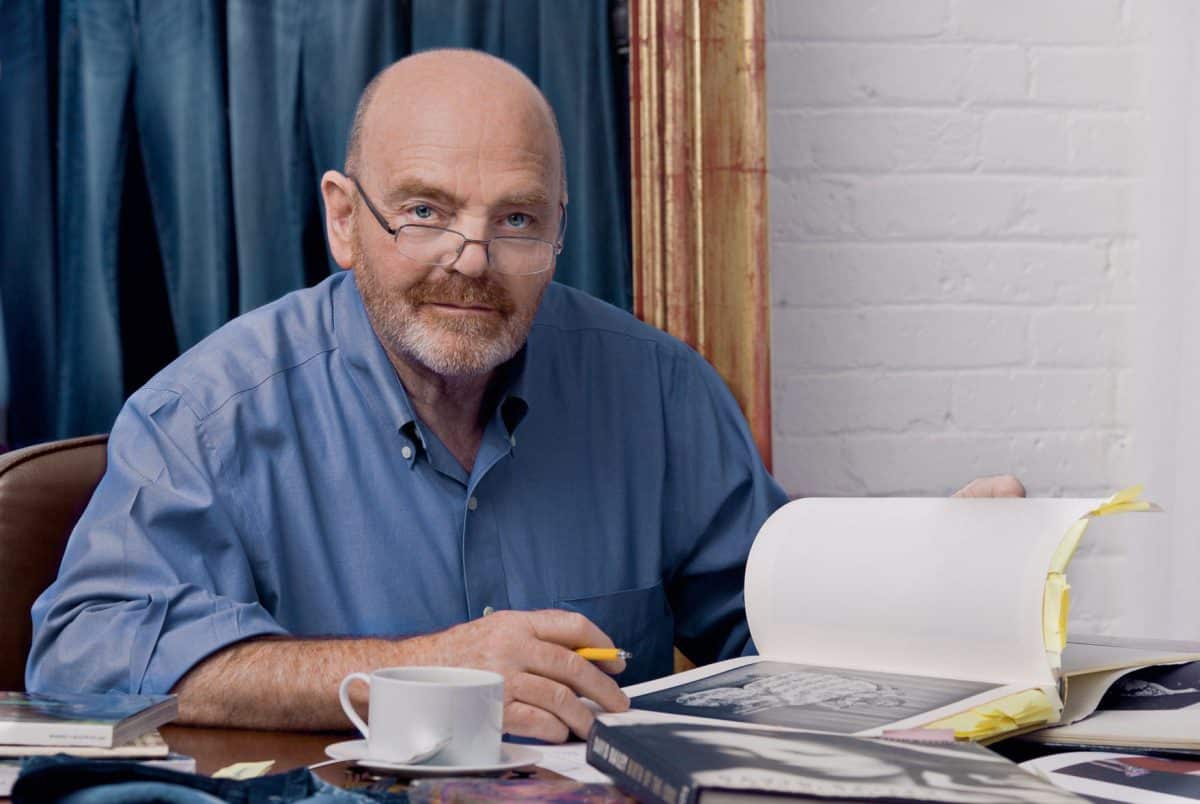

This blog post is an adapted excerpt from Blue Blooded. It was written by my co-author of the book, Josh Sims. If you don’t have Blue Blooded already, you can get it here.

Looking Back at Cone Denim’s White Oak, Which Sadly Soon Is No More

In the immortal words of Axl Rose (and probably someone before him), “nothin’ lasts forever.”

Still, there are some things you expect never to disappear. Imagine if Coca-Cola went out of business. Or Harley Davidson. Or Jack Daniel’s. It’s unimaginable, right?!

Cone Denim’s White Oak plant in Greensboro—or ‘Jeansboro’—in North Carolina is to denim what those brands are to soft drinks, motorcycles and liquor, respectively. White Oak is so quintessentially American that it almost hurts. It’s got a history that any other denim maker could only dream of. Not to mention a great product!

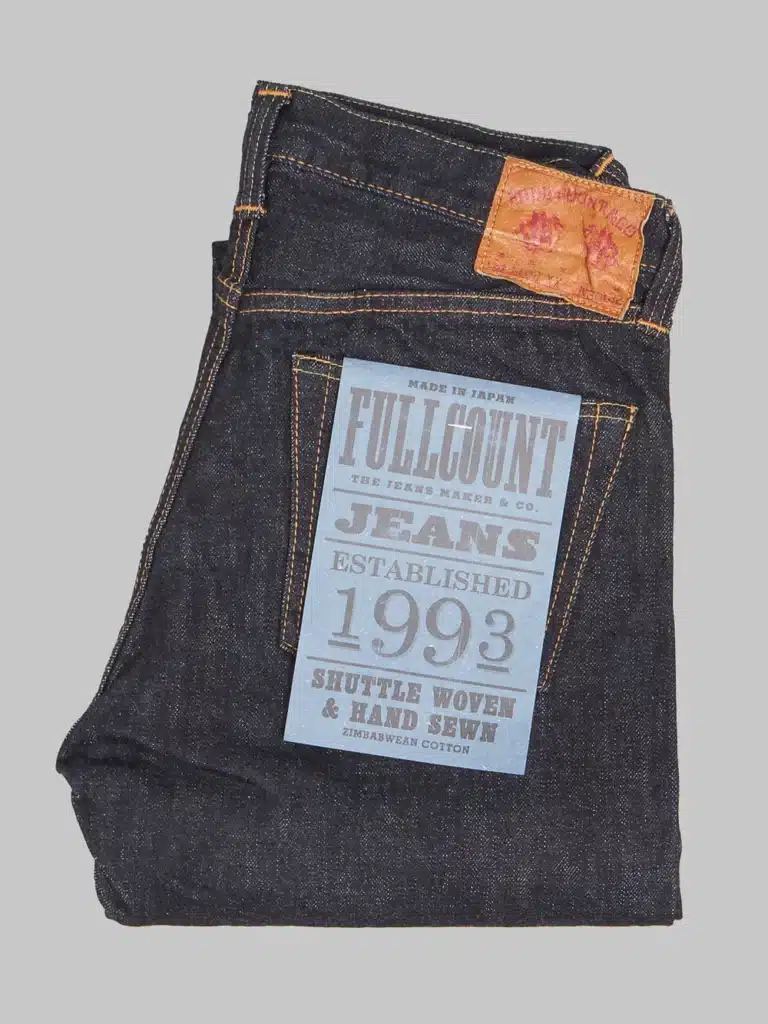

Hand-Picked Must-Haves and Essentials

Sorry to interrupt your reading but we’ve found these products that we really think you should take a closer look at!

Support us when you shop: We earn a small commission when you buy from these merchants.

A problem with White Oak, as I see it, is that—despite the enthusiastic support of committed brands and die-hard enthusiasts—it’s not something the average consumer recognises. It’s not a brand in the sense Levi’s is.

Since Josh wrote this company profile in the early spring of 2016, the owner of Cone Denim, International Textile Group, has been bought by the private equity investment firm, Platinum Equity, who recently announced that White Oak will cease operations on December 31, 2017.

It’s an unparalleled loss to the jeans industry, and to anyone who loves denim. Honouring White Oak and the plant’s legacy, I felt it fitting to share this profile. Call it a eulogy, if you will.

Looking for the Biggest Bang for Your Buck?

Great selvedge isn’t necessarily expensive. If you’re looking for big value for your money, your safest bets are: TCB 60s Regular Straight (€180), Japan Blue J301 ($185), and Sugar Cane 2009 ($195).

The Denim That Made Levi’s

Cone is to denim-weaving what Levi’s is to jeans-making. With a heritage stretching back well over a hundred years, the mill has been part of the evolution of denim from the start, and its story intersects with the warp and weft of the entire industry.

It would be accurate to describe Cone Mills of Greensboro, North Carolina as legendary. “In fact,” says Ken Kunberger, Cone’s CEO, “although it has innovated many denims, its biggest contribution is just being there right alongside all the U.S. companies that built the denim business. Cone is interwoven into the story of denim. We’ve covered a lot of backsides.”

Established in 1891 by German immigrant brothers Moses and Caesar Cone, Cone Denim is the United States’ oldest denim manufacturer that is still in operation, producing 100 million yards of denim per year.

Of course, with Cone also making denim in Mexico and China, and pioneering new products like stretch denims, perhaps only a tenth of its output is selvedge denim—the kind that was used in nearly all Levi’s garments from 1915 through the mid-1980s and that has inspired many a Japanese reproduction.

The Heart of White Oak; Draper Shuttle Looms

Cone’s famed selvedge denim has been made in the White Oak plant since it was purchased in 1905, and so called because the plant once stood in the shadow of a giant oak tree.

Here, the denim is made on American Draper shuttle looms, the last remaining in operation anywhere (and, as far as Cone is aware, of a variety that never made it to Japanese shores, denim myth-making aside).

“To see them in production is like going through a museum, back through a century-old facility, with the looms bouncing on the wooden floor,” says Kunberger of a scene that would have been commonplace in 1908, when Cone was the world’s single biggest manufacturer of denim.

There’s a music to them. For denim aficionados, it’s like an Elvis fan going to Graceland.”

Such looms may be few and far between these days. When it needs more, Cone sources them from junkyards across the American South. Many of them are little more than bare metal and require extensive and prized expert restoration work to get them into production.

It’s their bounce—their so-called ‘loom chatter’—that gives rise to one of White Oak denim’s most distinctive characteristics: the slubs resulting from low-tech yarn spinning, alongside a red cast and a certain “neppy” quality.

It’s this, as well as the fact that it is an American-made product, that has seen any number of artisanal American jeans makers, from Tellason and Raleigh to Left Field and Rising Sun, choose to use White Oak, often to develop exclusive fabrics.

The 2003-Bankruptcy and Following Revival

Still, the revival of interest in artisanal denim products came as something of a surprise to Cone.

In 2003, the company went bankrupt, and it was thanks to the company’s purchase soon after by Wilbur Ross—and its subsequent amalgamation into the new International Textile Group—that Cone lived on, buoyed by renewed demand for White Oak denim.

We think that demand is here to stay, too,” says Kara Nicholas, Cone’s vice president of product development. “It’s not some trend for the ‘old- fashioned’ but a demand for the quality of the fabric, and because people want more of a story in their garments. They want to be part of the heritage.”

Or as self-professed car guy Kunberger says, “people won’t ever lose interest in a 1968 Mustang, even if there are more advanced, brand-new production cars around. There will always be people who want the Mustang, regardless.”

Now at the vanguard of American denim manufacturing, Cone stands up against the many high-end mills in Japan and increasingly around the world.

Cone admires and welcomes the competition, but Kunberger notes how even Japanese makers tend to be “every bit as enamoured of Cone.” Cone may be eclipsed in some handcrafts, but it is unlikely to ever be eclipsed in history.

Best Places to Buy Well-Made Menswear

Whether you’re looking for a pair of selvedge jeans, a denim jacket, a loopwheeled T-shirt, or anything that is made slowly and purposefully, start your search with these brands and retailers:

Support us when you shop: We earn a small commission when you buy from these merchants.

Epilogue

It’s almost tragicomical how less than two years after Josh wrote those final words in his profile of America’s last denim manufacturer we’re now coming to grip with the fact that from January 1, 2018, there will be no more White Oak.

Some of the first to learn about the fate of Greensboro’s proud denim maker was Tellason founders, Pete Searson and Tony Patella.

When our friend and manager of the Cone Mills office in San Francisco called on the morning of October 18 and asked us if we were sitting down, we knew what he was going to say,” they write in a statement on their Facebook page.

The big surprise came a few months earlier when they learned that their brand was the fourth largest customer at White Oak. They were rightly thinking, “where are the big brands?”

Pete and Tony visited White Oak a couple years ago. “We saw the beautiful antique looms humming along, producing some of the most coveted denim in the world. We saw the spun yarns taking dips in indigo baths. We witnessed the pride the workers had in being a part of something historic, something important. The faces of these people and the memories of meeting them are the first thoughts we had when we heard of White Oak’s closure.”

They remind us, though, that entities like White Oak are businesses, not museums. They suggest that the best way to support them is with your wallet!

This denimhead can only hope (and expect) that the mythical Draper looms will somehow continue to make denim. Maybe one of the big brands steps up and picks up what’s left of White Oak? (Levi’s and VF, I’m looking at you!) Or, who knows, maybe they’ll be going to Japan, turning the myth of all denim myths (that the Japanese bought American looms) to truth?

As suggested further reading, I recommend you to take a look at Heddels co-owner, David Shuck’s defence of Cone Mills from 2015. The series of blog posts that WGSN’s Samual Trotman wrote that same year in celebration of the centennial of the ‘golden handshake’ between Levi’s and Cone is also excellent.

Selvedge Masterlist Top Three Jeans

The list of our favourite Japanese selvedge jeans is long, but at the very top of it, you’ll find: Iron Heart 634S, Samurai S710XX, and ONI 622ZR.

Share